|

|

|

Plastic formwork systems: EH, EE series

Plastic

formwork systems: EH, EE series are new word in monolith building.

It helps to make building process easier. Our offered formwork

systems satisfy all the requirements not only for product quality,

but for building quality, too. Formwork systems are very popular

in civil and industrial engineering in Asia and America. In the

years 2006-2008 formwork systems has been modernized many times.

All the defects discovered in practice are averted, panel construction

is lightened, and industrial technologies are improved. Manufacturing

process started with «G» panels. As plastic formwork systems in

some way are innovation, «G» panels were pilot batch. Analyzing

working with these panels ways of product improvement were found.

On the base of received information «EH» panels manufacturing

has started. The main difference from «G» panels was in technical

characteristics - ribbed stiffener. It is easy to use «ЕН» panels

because assembling process is facilitated. Since the year 2008

FUVI COPPHA is developing new product - «EZ» panels. From prior

products «EZ» panels differ with greater lightness despite previous

load factors. Plastic

formwork systems: EH, EE series are new word in monolith building.

It helps to make building process easier. Our offered formwork

systems satisfy all the requirements not only for product quality,

but for building quality, too. Formwork systems are very popular

in civil and industrial engineering in Asia and America. In the

years 2006-2008 formwork systems has been modernized many times.

All the defects discovered in practice are averted, panel construction

is lightened, and industrial technologies are improved. Manufacturing

process started with «G» panels. As plastic formwork systems in

some way are innovation, «G» panels were pilot batch. Analyzing

working with these panels ways of product improvement were found.

On the base of received information «EH» panels manufacturing

has started. The main difference from «G» panels was in technical

characteristics - ribbed stiffener. It is easy to use «ЕН» panels

because assembling process is facilitated. Since the year 2008

FUVI COPPHA is developing new product - «EZ» panels. From prior

products «EZ» panels differ with greater lightness despite previous

load factors.

Basic benefits

using plastic formwork - Re-use Rate up to 100

times. Panels are carefully engineered and tested to endure the

hard working conditions that are related to the building and construction

industry.

- Easy to assemble

Panels are joined with (I-pin) inserts from the back side of the

panel living no joint marks on concrete surface. - Various

sizes, slide fitting capability. Various sizes are available,

different length and width to fit your needs. Size up to 500x2000

mm. Panels can slide fit to any corner, dimension and difficult

intersections.

- Smooth panel surface. Minimize concrete adhesive thereby giving

a smooth concrete surface and maximize re-usage rates.

- Lightweight panels. Each plastic panel (8-11 kg/m2) can be handled

easily by one person, so there is no need to use additional equipment

for transporting and assembling.

- Follow-up-work nonbeing. There is no need for panel internal

surface treatment with special liquid, because all the tests proved

that panels have no adhesion with concrete.

- Easy to clean and store. The smooth plastic surface does not

bond to concrete, does not require mold oil application. Panel

makes the stripping process very easy and reguire only water cleaning

for easy storage. 1000m2 formwork can be stored at area of 23m2.

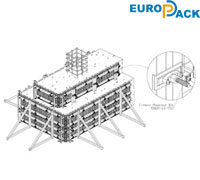

Foundation

forms

Panels are made of tough plastic. As a result panels are very

light and safe in comparicon with other traditional formwork.

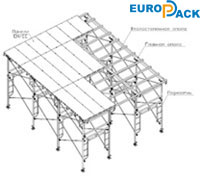

Slab

forms

Panels are especially designed to simplify and be more user-friendly

for workers.

Beam

forms

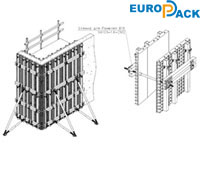

Wall

forms

With smooth panel surface you can be assured of project quality

and on time project completion.

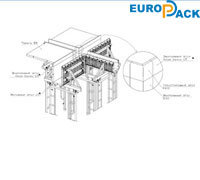

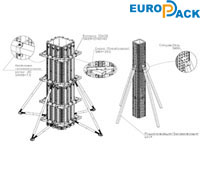

Column

forms

Extensive range of standard sizes of formwork enables you to construct

a wide range of combinations for column forms.

Panel

connection schema

Different formwork type comparison

| Description |

Usage rate |

Investment costs |

| Plywood formwork |

Up to 5-7 times |

Repeated investments

are required. |

| Metal formwork |

Up to 30 – 50 times |

High maintenance cost

is required to maintain usage rate. |

| Plastic formwork |

Up to 100 times |

1 time investment.

No maintenance. |

Cleaning and storage

Fuvi Plastic panels are easy to clean with simple water hosing, store

in flat sheet form.

Conventional application

using plastic formwork

- billboards with UV surface protection, no color fading;

- outdor field coverage (protect grass infields);

- walkways and train platforms (non-slippery);

- storage facilities and shelves (quick and easy to assemble);

- outdoor exibition/trade show flooring (elevant frame to allow electrical

wires and signal cables to be routed safely underneath);

- performance/concert stages (withstand heavy loads).

back

|

|

|

|

|

|

All rights reserved 2008. European Construction Systems LLP

|